COMMON PROBLEMS

Elevators are a key requirement in multi-storey buildings and measures like social distancing and regular cleaning can create long delays. Cleaning is often impractical during the busiest periods and cannot prevent airborne infections.

Viruses, bacteria, allergens and mould are constantly present in the air around us, with the design of many buildings and air handling systems increasing the chances of them being distributed across wide areas. High numbers of individuals pass through an elevator in a working day. The more people passing through an area, the higher risk of infections spreading which increases absenteeism and associated costs.

A person unknowingly harbouring an airborne infection can spread the associated risk over a large area. Individuals who can be conscious of not coughing or sneezing in more public areas may be much less concerned about the same activities in “unseen areas” like an elevator which is another reason controlling microorganisms here is an essential part of any company’s infection control strategy.

ADDITIONAL PRODUCT BENEFITS

> Proven to kill viruses and bacteria › Eliminate unpleasant odours

> Enhanced protection for both staff and visitors

> Fan driven for consistent performance

> Safe and suitable for use in enclosed areas of continuous occupation

> Single unit offers coverage of up to 18m3

> Maintenance only once per year

> Technology proven to reduce absenteeism

> LED indicator confirms correct unit operation and advises when lamp change required

PERFECT FOR USE IN

> Shopping Mall Elevators

> Hotel Elevators

> Hospital Elevators

> Residential Elevators

> Cargo Elevators

> Warehouse Elevators

HOW AIRSTERIL TECHNOLOGY WORKS

A unique balanced combination of technologies working together:

Internal Technology

• Germicidal Irradiation by Ultaviolet light kills microorganisms

• PCO – Photocatalytic Oxidation breaks down harmful Volatile Organic Compounds.

• Dual waveband UV combined with the catalyst both creates and breaks down Oxygen molecules generating Ozone and Superoxide Ions, air leaves the unit as “Plasma Quatro”

Transmitted technology

• Air leaves the unit as Plasma Quatro, it is propelled from the unit and will then fall towards ground level removing contaminates in its path:

• Superoxide Ions charge airborne contaminates causing them to cluster together and fall from the air as they become too heavy, aiding all other processes. This can remove airborne particulates down to 0.001 microns.

• Targeted Ozone gets to the hardest to reach areas breaking down contamination and creating a fresh pleasant environment.

The custom designed system ensures that contaminated air processed through the unit achieves optimum dwell time in the purifying chamber. As the processed air leaves the unit, it then itself becomes an efficient cleaning agent.

HOW OUR SAFESPACE SYSTEM WORKS

THE MOST ADVANCED ELEVATOR CAR DISINFECTION TECHNOLOGY

All AIRsteril units utilise our unique combination of 5 technologies. They eliminate unpleasant odours and control harmful bacteria and viruses 24 hours a day, 365 days of the year.

Operation is indicated by a green indicator LED within the centre of the outlet vent, this confirms the lamp at the core of the treatment chamber is working well. The unit lamp requires replacement after 12 months of operation, the indicator LED changes to red in order to highlight when the lamp requires replacement.

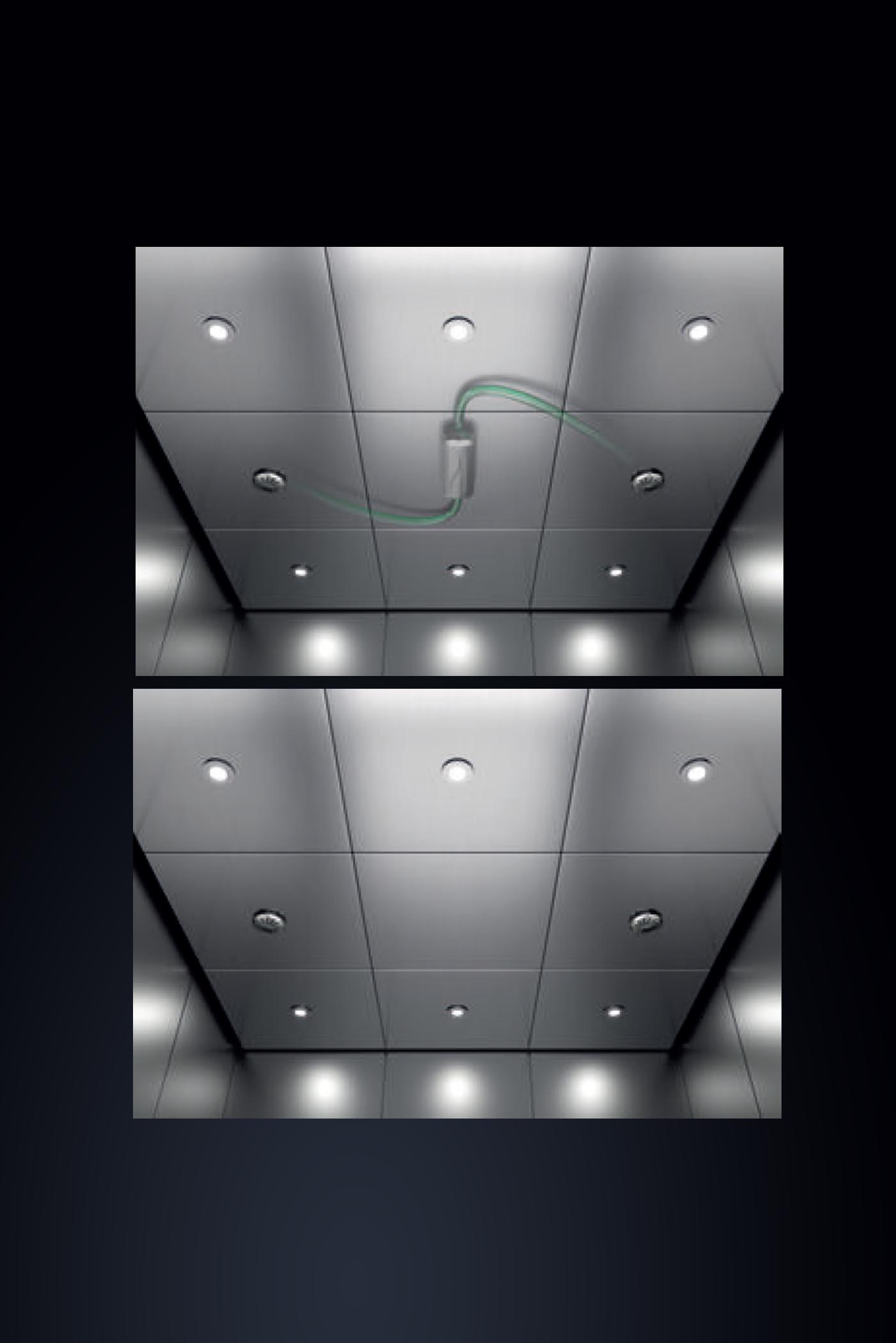

The Safespace elevator range units are specifically designed for conttinuous operation via a fused spur, in elevators or similar environments where a concealed unit is required.

OPERATION AND SAFETY

The unique balance of technology used by AIRsteril has been tried, tested and refined over many years to ensure the best achievable results with every unit is supplied.

– Due to the unit design, UV light cannot escape the unit from any angle meaning it is completely safe.

– Ozone levels used are substantially below the most stringent emissions regulations in the world.

– All electrical connections enter the unit via a single insulated cable and are completely shielded internally by the cover.

HOW OUR SYSTEMS WORK

The advanced technology of the AIRsteril Thermal U/V unit allows the control of bacteria, viruses and moulds both in the air and on surfaces more efficiently than ever before. All of this is achieved without fans and with very low energy consumption. The custom designed thermal convection system ensures that contaminated air processed through the unit achieves optimum dwell time in the purifying chamber. As the processed air leaves the unit, it then itself becomes an efficient cleaning agent, targeting pathogens both in the air and on surfaces.

*Certain bacteria such as Ecoli can replicate every 20 minutes, which could in theory leave you with 16.7 million in 8 hours, what we are highlighting is that bacteria breed very quickly and cannot be controlled with traditional methods.

TECHNICAL DETAILS

DIMENSIONS //

410mm (L) x 130mm (W) x 95mm (D)

POWER SUPPLY //

220-240V, 50-60Hz 17watts

SET UP //

Unit concealed with only inlet and outlet vents visible in cab ceiling

CONSTRUCTION //

Polycarbonate moulding

WEIGHT //

1.5kg

OPERATION //

Continuous operation

SERVICING MADE EASY

Power must be disconnected before attempting any servicing and only undertaken by a competent individual. All AIRsteril suppliers can arrange fully trained engineers to carry out servicing work

The cover is easily removed by loosening screws, then the lamp can be replaced and dust or debris build up cleared from the fan and interior.

Once power is re-activated the LED lamp reminder system is reset. Lamps must be changed on an annual basis to maintain performance.

Reviews

There are no reviews yet.