PRIMARY FUNCTION

The primary function of the In-duct units is to keep the AHU (air handling system) and ducts themselves clear of contamination. Keeping the ducting system clear of harmful microorganisms is not significantly impacted by air flow, and generally we would expect air being sourced for a system to be relatively clean without contaminates If units are required to treat the air flowing through the system then calculations become much more complicated, air flow is the most obvious point, however other points to consider are as below:

> What kind of air is the duct carrying (fresh air should be clear of contamination, recirculated air understandably may require treatment, but units within rooms may be a better solution)

> Duct dimensions (size and shape of duct) can impact the air speed past the units

> Duct material (aluminium, stainless steel and galvanised steel have different reflective capabilities with UV-C light)

> Air quality (air should not contain any dust, but quality of initial filtering can increase challenge)

> Age of system (older systems will be prone to greater internal contamination and air loss)

> Air temperature (our lamps are insulated against temperature changes and the protective sleeve around each lamp ensures peak efficiency)

PERFECT FOR USE IN

> Air Handling Units

> Ducting systems

> Air Conditioning systems

HIDDEN EFFECTS OF POORLY MAINTAINED AIR SYSTEMS

> Odour issues meaning visitors perceive poor hygiene, lack of care and poor management

> Higher cleaning costs and premature refurbishment

> Increased health risks including; spreading of illness and allergy

> Increased absenteeism and staff turnover

> Efficiency of air handling units decrease

HOW AIRSTERIL TECHNOLOGY WORKS

PHOTO CATALYTIC OXIDIZATION POWERPACK UNIQUE TO AIRSTERIL

A combination of technologies working together:

Internal

– Germicidal Irradiation by dual UV light (Ultraviolet) kills microorganisms (bacteria, viruses and mould) by disrupting their DNA and removing their reproductive capabilities.

– PCO – Photocatalytic Oxidation, UV reacts with our Catalyst (Ti02) to form highly reactive but short lived oxidising Hydroxyl Radicals (OH) which break down Volatile Organic Compounds (VOCs).

– Interaction of the Dual waveband UV with the TiO2 heterogeneous catalyst both creates and breaks down Oxygen molecules transforming Oxygen into a highly reactive states of Ozone and Superoxide Ions which leave the unit as

“Plasma Quatro”.

Transmitted Technology

– The negatively charged Superoxide Ions charge airborne contaminates causing them to cluster together and fall from the air as they become too heavy, aiding all other processes. This can remove airborne particulates down to 0.0001 micron, that’s better than any HEPA filter.

– Targeted Ozone produced via the specialist lamp gets the hardest to the hardest to reach areas breaking down contamination in the air and on exposed surfaces. Ozone damages the cell wall of microorganisms stopping reproduction and destroying the cell.

HOW OUR IN-DUCT SYSTEM WORKS

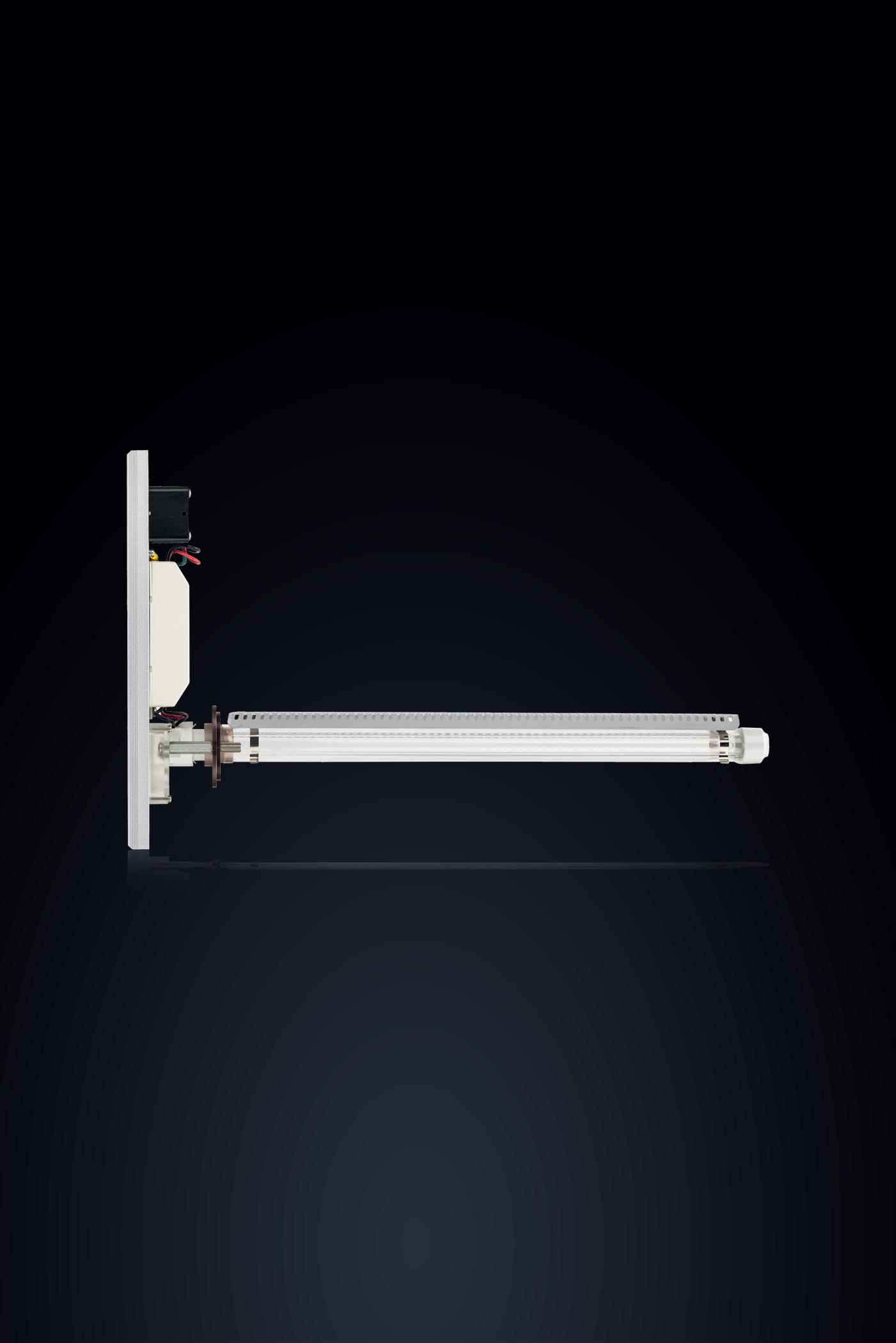

These units are designed to permanently fixed into ducting systems and the powerful germicidal lamp will target airborne microorganisms as well as surface contamination within the ducting system, the Catalysts interact with the UV to quickly break down odourous volatile organic compounds through PCO. Using temperature insulated, shatterproof wrapped lamps they significantly contribute to compliance with safety standards in a variety of industries. Dependent on site conditions and installation location a single unit or multiple units may be required to eliminate growth of mould and control bacteria throughout an air handling unit or ducting system.

The In-duct should be operated 24/7 to spread purifying air through the ducting system and building utilising the airflow generated by the ventilation system.

OPERATION AND SAFETY

The unique balance of technology used by AirSteril has been tried, tested and refined over many years to ensure the best achievable results with every unit is supplied.

> Due to the unit design UV light cannot escape the unit from any angle meaning it is completely safe.

> Ozone levels used are substantially below the most stringent emissions regulations worldwide.

> Power via a plug with an inline switch allows flexible installation and easy connection to existing sockets.

AIRSTERIL IS AN IDEAL SOLUTION

*Certain bacteria such as Ecoli can replicate every 20 minutes, which could in theory leave you with 16.7 million in 8 hours, what we are highlighting is that bacteria breed very quickly and cannot be controlled with traditional methods.

TECHNICAL DETAILS

DIMENSIONS //

280mm (l) x 156mm (w) x 65mm (d) – In-Duct

POWER SUPPLY //

120 – 277V, 50/60Hz AST2000 – 36 watts – In-Duct

SET UP //

Fixed through the wall/roof of ducting or air handling unit system using support frame and template

CONSTRUCTION //

Rugged construction, anodised aluminium

WEIGHT //

1.5kg – In-Duct

OPERATION //

Continuous operation

SERVICING MADE EASY

Switch off power.

Losses and remove the two retaining finger serews to allow removal of central / lamp section from within the duct.

Remove the two lamp retaining screws allowing the lamp to be changed, then replace the screws.

Re-fit the central unit into the support frame, tighten the two retaining finger screws and attach the unit back in its placement.

Turn on the power. The lamp’s blue light will be visible through the rear of the unit.

DO NOT LOOK DIRECTLY INTO THE LAMP

Reviews

There are no reviews yet.