HOW CAN THE ULTIMATE SMALL AREA UNIT ACHIEVE RESULTS

AIRsteril utilise indirect UV-C enclosed within a chamber so there is no risk to personnel or the environment. The Ultimate SA unit is the newest model in our food grade range, bringing the technology of our larger Ultimate range into smaller areas whilst retaining the key elements from the larger units allowing the control of bacteria and VOCs more efficiently than ever before.

All of this is achieved with low energy consumption, only 22 watts. The custom designed baffle system ensures that contaminated air processed through the unit achieves optimum dwell time in the purifying chamber. As the processed air leaves the unit it becomes an efficient cleaning agent, targeting pathogens in the air and on surfaces, reaching areas where traditional disinfection is not possible.

The AIRsteril Ultimate SA unit output can be adjusted as required for room volume and usage, to control harmful bacteria and viruses both in the air and on all exposed surfaces 24 hours a day, 365 days of the year. A single Ultimate unit can cover areas up to 110m3.

*Certain bacteria such as Ecoli can replicate every 20 minutes, which could in theory leave you with 16.7 million in 8 hours, what we are highlighting is that bacteria breed very quickly and cannot be controlled with traditional methods.

ODOUR AND INFECTION CONTROL IN

> Industrial Kitchens

> Food Processing

> Food Chillers

> Boning Halls

> Cold Storage

AIRBORNE SURFACE BACTERIA

Testing demonstrates AIRsteril technology can have a beneficial effect on spoilage bacteria on food throughout the food chain. Our technology is effective on airborne and surface bacteria and is safe to use in occupied areas.

| Area upto | 110m2 | 220m2 |

| Food processing, food chillers, boning halls, industrial kitchens, etc. | ULTSA | 2 x ULTSA |

HOW AIRSTERIL TECHNOLOGY WORK

A combination of technologies working together:

Internal

– Germicidal Irradiation by dual UV light (Ultraviolet) kills microorganisms (bacteria, viruses and mould) by disrupting their DNA and removing their reproductive capabilities.

– PCO – Photocatalytic Oxidation, UV reacts with our Catalyst (Ti02) to form highly reactive but short lived oxidising Hydroxyl Radicals (OH) which break down Volatile Organic Compounds (VOCs).

– Interaction of the Dual waveband UV with the TiO2 heterogeneous catalyst both creates and breaks down Oxygen molecules transforming Oxygen into a highly reactive states of Ozone and Superoxide Ions which leave the unit as “Plasma Quatro”.

Transmitted Technology

– The negatively charged Superoxide Ions charge airborne contaminates causing them to cluster together and fall from the air as they become too heavy, aiding all other processes. This can remove airborne particulates down to 0.0001 micron, that’s better than any HEPA filter.

– Targeted Ozone produced via the specialist lamp gets the hardest to the hardest to reach areas breaking down contamination in the air and on exposed surfaces. Ozone damages the cell wall of microorganisms stopping reproduction and destroying the cell.

HOW OUR ULTIMATE SYSTEM WORKS

All AIRsteril units utilise our unique combination of 5 technologies. They eliminate unpleasant odours and control harmful bacteria and viruses 24 hours a day, 365 days of the year.

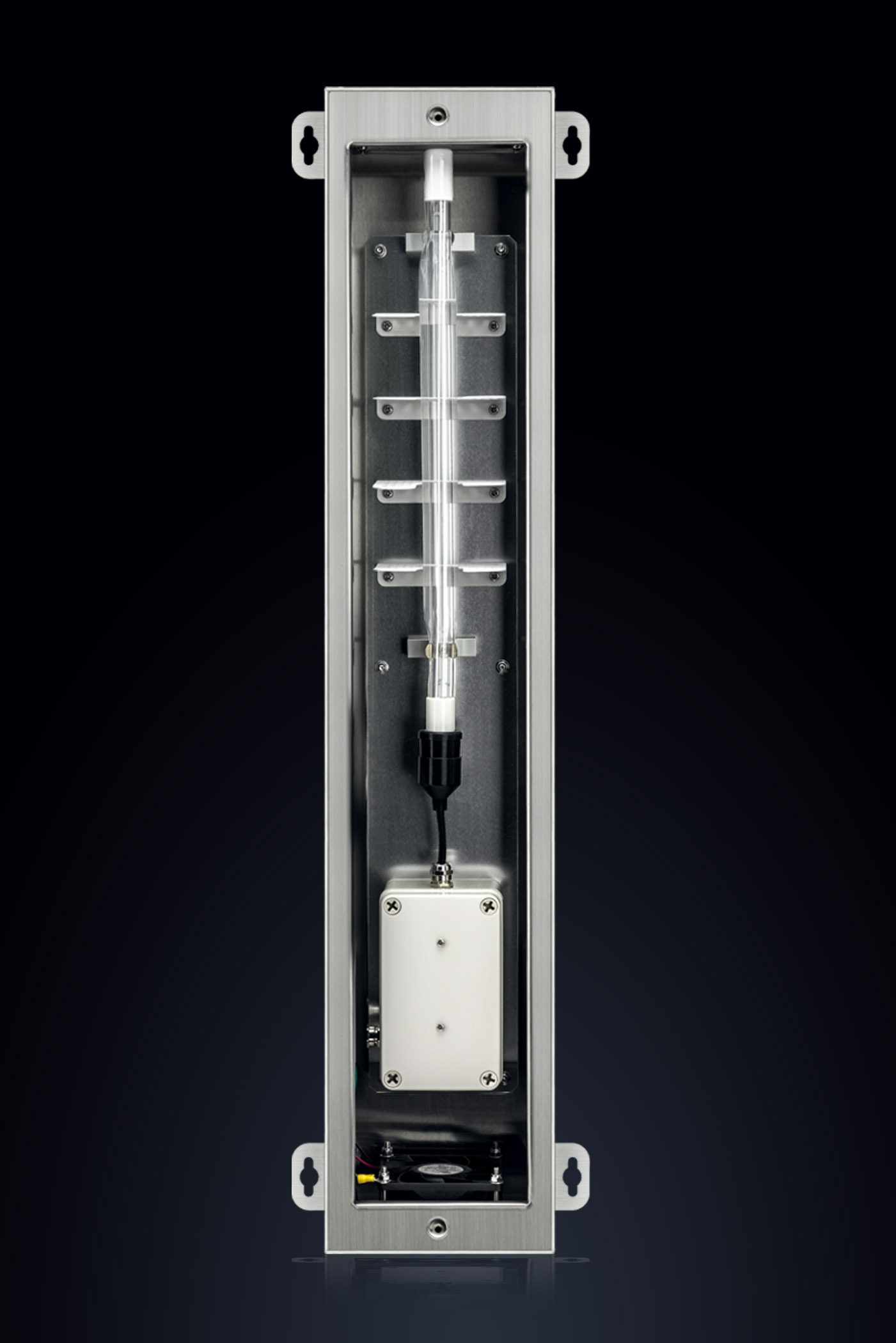

The Ultimate SA units are designed specifically for use in food processing. With their robust stainless steel construction and water resistant qualities, they offer continued microbial reduction from air and surfaces to ensure best practice is maintained.

Units must be wall mounted to maximize performance and in continuous operation. A single unit can control harmful bacteria and viruses in an area up 110m3.

TRIALS FROM SLAUGHTER TO RETAIL

Microbiological standards within slaughter processing plants in the European Union are currently governed by Commission Regulation (EC) 2073/2005, which describes detailed performance criteria at specific stages of the procedure (following carcass dressing) for total viable counts (TVC), Enterobacteriaceae (EB) and Salmonella spp.

In this study, 18 carcasses from a slaughter plant were sampled by swabbing after slaughter and after 48 hours chilling, with 9 carcasses in a chiller containing AIRsteril technology and 9 in an untreated control chiller.

Significant reductions in TVC for all carcasses after chilling in the treated chiller, but no marked difference in TVC levels on carcasses within the untreated chiller.

Results show that contamination can be significantly reduced at various steps in the process and highlight the importance of monitoring locations other than those required by legislation within the process.

AIRsteril technology can have a beneficial effect on spoilage bacteria on food throughout the food chain. Our technology is effective on airborne and surface bacteria and is safe to use in occupied areas.

HOW OUR SYSTEMS WORK

The advanced technology of the AIRsteril Thermal U/V unit allows the control of bacteria, viruses and moulds both in the air and on surfaces more efficiently than ever before. All of this is achieved without fans and with very low energy consumption. The custom designed thermal convection system ensures that contaminated air processed through the unit achieves optimum dwell time in the purifying chamber. As the processed air leaves the unit, it then itself becomes an efficient cleaning agent, targeting pathogens both in the air and on surfaces.

*Certain bacteria such as Ecoli can replicate every 20 minutes, which could in theory leave you with 16.7 million in 8 hours, what we are highlighting is that bacteria breed very quickly and cannot be controlled with traditional methods.

TECHNICAL DETAILS

DIMENSIONS //

550mm (l) x 250mm (w) x 125mm (d)

POWER SUPPLY //

220-230V 22 watts

SET UP //

Wall mounted. Easy for marking, four fixing points.

CONSTRUCTION //

Stainless steel extrusion, IPX 5 Waterproof rating.

WEIGHT //

6kg

OPERATION //

1 x 20W specialist UV lamps 24v DC IP68 Fan with 150 CFM free air flow.

OPERATION AND SAFETY

The unique balance of technology used by AIRsteril has been tried, tested and refined over many years to ensure the best achievable results with every unit is supplied. – Due to the unit design UV light cannot escape the unit from any angle meaning it is completely safe. – Ozone levels used are substantially below the most stringent emissions regulations worldwide – IP65 Waterproof unit rating ensures safe and ongoing operation in the toughest environments. – Food grade wrapped lamps prevent any risk to food chain

Reviews

There are no reviews yet.